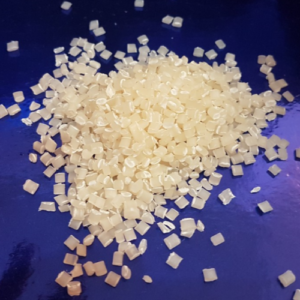

Good quality Bioplastics resin with good price in Vietnam

As a unit specializing in the production of Bioplastics on tapioca starch, which is a popular crop in Vietnam. Our Company’s Bioplastics have reached the standard of biodegradation according to international standards and are recognized by prestigious organizations in the world:

@ US Department of Agriculture – USDA: Certified products with renewable biological ingredients.

@ TUV-AUSTRIA Organization (2 stars): Product certified with renewable biological ingredients and 100% Food Safe without harmful ingredients and heavy metals.

@ Eurofins Organization: Certified to meet REACH/ROHS (EU) food safety standards and FDA (US) standards.

@ Vinacontrol Organization: 100% food safety certification does not contain toxic ingredients and heavy metals.

@ Center 3 (Quatest 3) under the Ministry of Science and Technology: Certification of environmentally friendly products and biodegradation standards within 6 months according to Circular 07/2012/TT-BTNMT.

Introducing Nam Trung Viet bioplastics

Nam Trung Viet Company is a comprehensive solution provider for bioplastics from fully biodegradable raw materials to finished products and professional technical consulting services in Vietnam and other countries around the world.

With a team of experienced, professional, and dedicated staff, Nam Trung Viet has affirmed its position and became a reputable partner in the field of supplying fully biodegradable materials and products. Furthermore, we have been trusted and chosen by many domestic and foreign enterprises for advising on the business strategy towards “Go Green”, developing solutions and supporting on technology and production process.

Grasping the green consumption trend in the world, Nam Trung Viet targets businesses in Vietnam and other countries with policies of limiting disposable plastic products to protect the environment such as Europe, America, Thailand, Korea, Indonesia … As a biodegradation supplier and a comprehensive strategic planner, we are confident to meet diverse requirements with the highest quality and at the most competitive prices.

We have two Bioplastics plastic material codes with specifications to make the following products

1. Typical Material Properties Bioplastics

Application in packaging and coating film (T-shirt bag, shrink film, agricultural mulch).

| Properties | Unit | Test method | Value |

| Melt Flow Rate | |||

| Melt flow rate (190oC/5.0 Kg) | g/10 min | ASTM D1238-10 | 1.58 |

| Mechanical Properties | |||

| Elastic modulus | MPa | ASTM D638 | 50.3 |

| Tensile strength at weld (v=50mm/min) | MPa | ASTM D882 | 18.1 |

| Tear strength (v=50mm/min) | N/mm | ASTM D1004 | 108 |

| Impact resistance by the free falling – dart | g | ASTM D1709 –

Method A |

32 |

| Thermal Properties | |||

| Melting point | oC | ASTM D3418-12 | 123 |

| Decomposition point | oC | ASTM E1131 – 08 | > 300 |

| Other Properties | |||

| Density | g/cm3 | ASTM D792 | 1.08 |

| Humidity | % | 0.37 | |

| Water vapor transmission | g/m2.24h | ASTM E96(Temperature: 38oC, Humidity: 93 %RH) | 26.64 |

| Cold resistance | The sample are placed in – 25oC environment, 2 hours | The sample is not cracked after 2hours | |

2. Typical Material Properties Bioplastics

Packaging industry and single-use plastic products (knives, spoons, forks, cups, straws (straight/twist), trays, boxes,

nonwovens, coffee capsule packaging, bags Vacuum).

| Properties | Unit | Test method | Value |

| Melt Flow Rate | |||

| Melt flow rate(230oC / 2.16 Kg) | g /10 min | D1238-10 | 6 |

| Mechanical Properties | |||

| Elastic modulus | MPa | D638 | 391 |

| Tensile strength | MPa | D882 | 27.83 |

| Notch izod impact strength | kJ/m2 | D256-10 | 2.75 |

| Shore D hardness | D2204-00 | 70 | |

| Thermal Properties | |||

| Melting point, DSC | oC | D3418-12 | 168 |

| Decomposition point | oC | E1131 – 08 | >300 |

| Other Properties | |||

| Density | g/cm3 | D792-13 | 0.963 |

Specifications bioplastics

Bioplastics Application on machines:

Extrusion, injection molding, lamination, bottle blowing, bag blowing, film blowing

Product bioplastics

Bioplastics time

Bioplastics time depends on product needs if you want your product to decompose quickly or slowly the decomposition time is 6 months 1 year 2 or 3 years we can adjust the time this for you it does not affect the quality of your product.

Quality

– Products are produced strictly according to national and international standards.

– We have CE, ISO certification

– We test every product before delivery.

Product price

– We can offer the lowest price compared to the market.

– We quote the earliest price for any customer.

– Price can be reduced according to quantity.

– Plastic products are produced strictly according to national and international standards.

– We have CE, ISO certification

– We test every product before delivery.