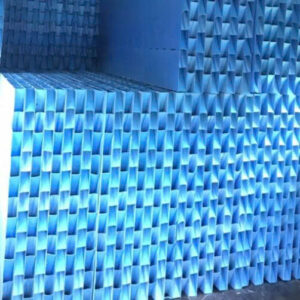

Kaldnes Biochip Media for MBBR System – Revolutionizing Biofilm Carriers

The Kaldnes biochip media for MBBR system is a high-performance biofilm support designed to elevate biological wastewater treatment. Specifically tailored for Moving Bed Biofilm Reactor (MBBR) technologies, this innovative media offers an impressive protected surface area exceeding 500 m²/m³, facilitating robust microbial growth and turbocharged treatment capabilities.

Whether your operation involves municipal sewage, industrial effluents, or aquaculture recirculation systems, this biochip media delivers enhanced process efficiency, compactness, and long-term stability.

|

|

|

|

|---|

What Is Kaldnes Biochip Media?

The Kaldnes biochip media for MBBR system consists of flat, disk-shaped polyethylene carriers engineered to maximize biofilm attachment. Each biochip floats freely in the reactor, providing microbes with an extensive surface to colonize, yet easily releases excess growth through natural tumbling action—ensuring continuous, clog-free performance.

Key Features

🌟 Ultra-High Surface Area

Boasting over 500m²/m³, this media supports dense biofilm populations essential for removing BOD, COD, nitrogen, and ammonia.

🌟 Premium Virgin Polyethylene

Crafted from non-toxic virgin PE, these biocarriers resist UV, abrasion, and chemical exposure, delivering a 15 to 20-year lifespan with minimal wear.

🌟 Slim & Lightweight Design

With a diameter of 25mm and thickness of approximately 1 mm, the biochips promote optimal mixing, aeration, and oxygen transfer—enhancing treatment kinetics without the need for oversized tanks.

🌟 Self-Cleaning Action

Through strategic movement in aerated conditions, the biochips continuously excel at shedding excess biofilm, preventing clogging and ensuring long-term operational stability with negligible maintenance.

How It Works in MBBR Systems

-

Biological solution flows into the MBBR tank, loaded with floating Kaldnes biochip media.

-

Microbes colonize the media surfaces, establishing dense biofilms.

-

Aeration and mixing maintain optimal oxygen and nutrient supply.

-

The movement of carriers triggers gentle scouring, removing excess biomass.

-

Treated effluent exits meeting stringent quality standards.

This dynamic process ensures consistent removal of organic pollutants and nitrogen compounds, even under variable loading or shock conditions.

Technical Specifications

| Specification | Value |

|---|---|

| Surface Area | 500 m²/m³ |

| Material | Virgin Polyethylene (PE) |

| Diameter | 25 mm |

High

|

10mm |

| Service Life | 15–20 years |

| Bioprocess Capacity | 500–1,400 g NH₄–N/m³·day |

These parameters ensure that the Kaldnes biochip media for MBBR system outperforms conventional carriers in both efficiency and lifespan.

Application Areas

-

Municipal wastewater treatment plants

-

Industrial effluent management (chemical, petrochemical, food processing)

-

Recirculating Aquaculture Systems (RAS)

-

Converting activated sludge systems into more efficient MBBR processes

This biochip media thrives under aerobic, anoxic, or even anaerobic conditions, making it highly versatile.

Advantages at a Glance

-

✅ Superior contaminant removal — enhanced BOD, COD, and ammonia degradation

-

✅ Space-efficient design — reduces footprint, ideal for retrofit projects

-

✅ Shock load resilience — maintains performance during flow and load fluctuations

-

✅ Minimal maintenance — self-cleaning media eliminates manual interventions

-

✅ Cost-effective — lower energy and operation costs over lifetime

-

✅ Scalable solution — increase capacity simply by adding more media

Conclusion

The Kaldnes biochip media for MBBR system redefines biological wastewater treatment — combining high surface area, robust durability, and effortless performance to offer sustainable, efficient, and cost-effective solutions. Ideal for new installations or upgrades, it empowers operators to design compact, high-capacity systems that consistently meet regulatory standards.

📩 Ready for the next step?

Contact us for technical consultation, sample requests, product datasheets, or quotations tailored to your project needs.

🔗 Internal Links (SEO Boost)

See also: [PVC Lamella Clarifier Plate]

📞 Contact Us

-

Email: ntvbioplastic@gmail.com

-

WhatsApp: +84 919 358 658

-

Facebook: facebook.com/namtrungvietenvi

-

Address: No. 88-90, 3rd Street, Him Lam KDC, Thu Duc City, HCMC, Vietnam